Compression and Tensile Force Measurements for Functional Control and Lifetime Testing

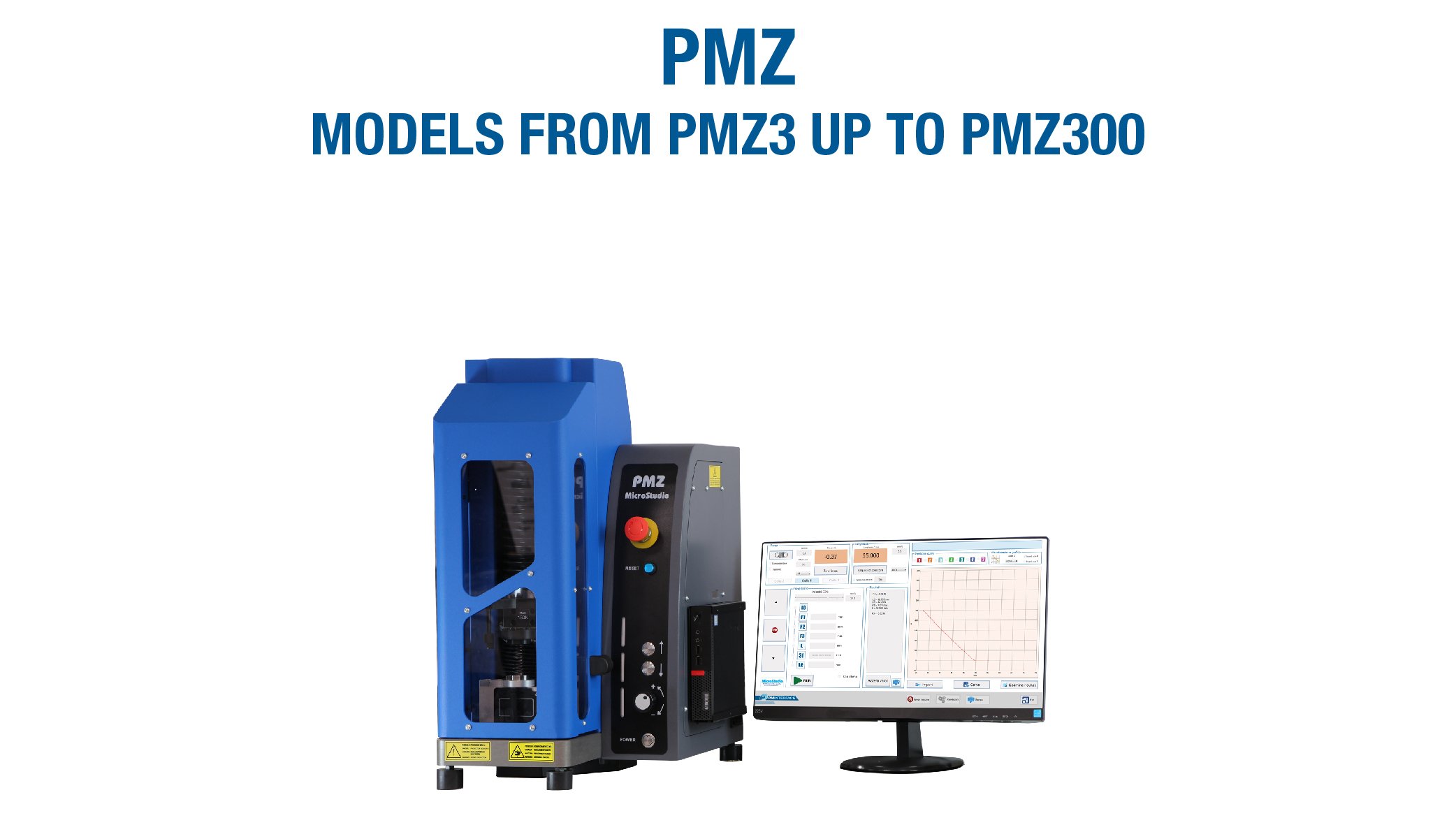

Within the measurement lab at Hermans Spring Factory, we have advanced setups and various machines at our disposal – including two Microstudio devices, our Shimadzu, and of course our PCM 500. These are used to analyze compression and tensile forces in the finest detail. These tests are the core of the functional quality control of our springs, wire products, and sheet metal components. They simulate realistic load conditions and ensure that every part can withstand the required forces and fatigue cycles.

What are compression and tensile force measurements?

This type of measurement examines how a material or product behaves under axial load – either in compression or in tension. Force, deformation, spring constant, and fatigue are all accurately recorded. The results provide a reliable picture of the mechanical properties of a component.

What are these measurements used for?

These tests are essential for:

- Determining the actual force-displacement characteristics of springs

- Checking the elastic and plastic limits

- Qualifying tensile strength and fatigue behavior

- Simulating real-world applications under actual loads

Our measurement capabilities:

- Force measurements from a few grams to 100,000 N (!)

- Stroke measurements up to 1400 mm

- Real-time analysis of force versus displacement

- Continuous data logging and comparison with standards or reference curves

Lifetime and Cycle Testing

Thanks to our cycle test setup, we can perform lifetime tests in which parts are subjected to loads for thousands to hundreds of thousands of cycles. This is crucial for applications where fatigue or metal fatigue is a factor. The evolution of forces and displacements is monitored to detect performance loss in time.