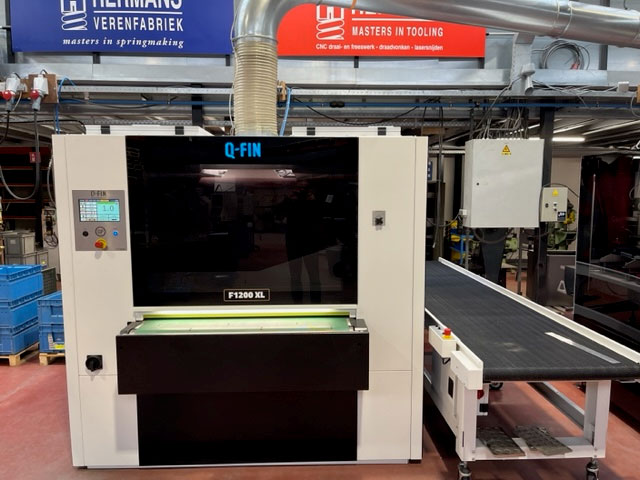

HERMANS VERENFABRIEK continues to invest in quality. For example, we have a complete deburring department. These machines can deburr, edge rounding, brush, sand and finish all products.

The result? Very short delivery times, both for piece and series work, including quality and precise HERMANS finishing.

A complete deburring department is of great importance in the sheet metal industry and can provide several benefits, including:

- Quality improvement: Sheet metal deburring is essential to remove sharp edges and burrs, which improves the overall quality and safety of products.

- Consistency: The use of deburring machines can achieve consistency and uniformity in finishing products, which is important for products that must meet specific standards and requirements.

- Efficiency: Automating the deburring process using machinery can make production more efficient and reduce lead times.

- Improved aesthetics: By removing burrs and sharp edges, finished products often look more attractive and professional.

- Customer satisfaction: The investment in deburring machines can lead to higher customer satisfaction because the products meet customers' expectations in terms of quality and finish.

- Deburring: This process involves removing sharp edges and burrs from materials, resulting in a smooth and safe surface. It is critical to prevent injuries and improve the overall quality of products.

- Edge rounding: edge rounding is the rounding of the sharp corners of a product. This can provide aesthetic benefits and make handling the product more comfortable. Edge rounding is often used in metalworking.

- Brushing: Brushing is a process in which a brush is used to polish or add texture to the surface of a product. It can serve to create a matte or satin finish and is often aesthetically pleasing.

- Sanding: Sanding is the removal of imperfections or leveling of surfaces by using sanding belts or abrasives. This process is often used to refine the surface of metal.

- Finishing: Finishing includes the final steps in machining the surface of a product to achieve the desired texture, gloss, or smoothness. It may also involve the application of protective coatings to improve durability and aesthetics.

The deburring department can contribute significantly to the quality and workmanship of the products offered.

The ability to deburr, edge round, brush, sand and finish all products is a valuable capability for a manufacturing company. This means that we are able to process a wide range of materials and products and provide them with the desired finish and quality. Here is a brief overview of each of these operations:

Personalize your item

For a personalized item, please fill in the text field.